Product: ArmaFix Thermal Brick Tie

Useful Links

ArmaFix Thermal Brick Tie

Product Information

Discover the Innovative ArmaFix Thermal Brick Tie by Coughlan Engineering (Tullamore) Ltd

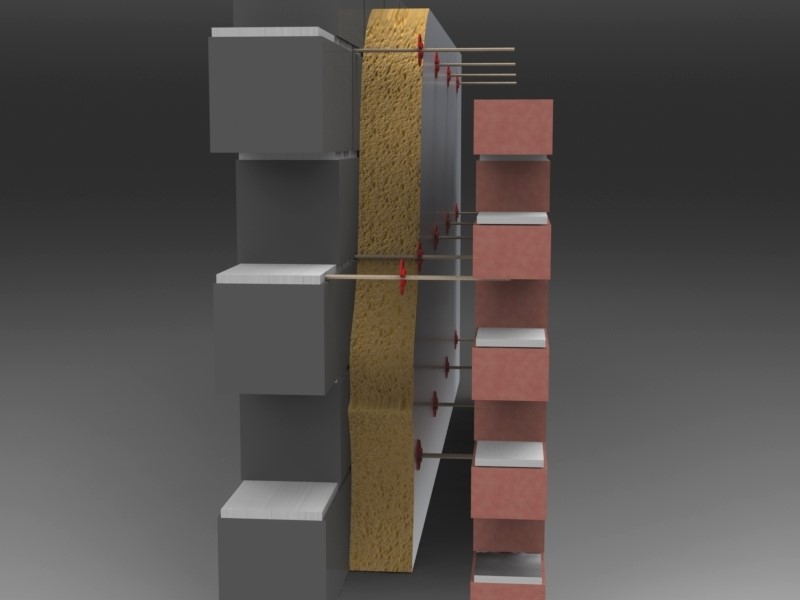

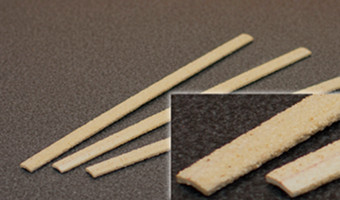

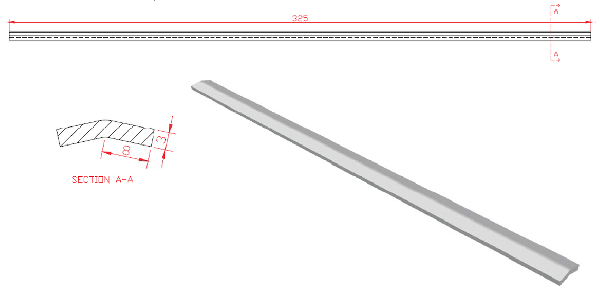

Coughlan Engineering (Tullamore) Ltd introduces the groundbreaking ArmaFix Thermal Brick Tie, designed to reduce thermal bridging in cavity wall construction. Our thermally insulating, symmetrical, horizontal composite wall ties are constructed with pultruded glass fibres embedded in a matrix of vinyl ester resin. With a coarse quartz finish, these ties provide excellent mortar joint bonding and moisture prevention across the cavity. Our wall ties are designed and certified for use in cavity widths ranging between 100mm and 200mm, complying with Type 2 classification as defined in BS 5628-1:2005 and Eurocode 6.

Achieve Structural Integrity with Proper Installation

Proper alignment of the mortar joints is essential to ensure the ArmaFix Thermal Brick Tie fit securely into each leaf, with a slight fall toward the outer leaf. The inner and outer leaf can be coursed concurrently or separately, following EN 845-1:2003 guidelines with a minimum mortar joint thickness of 10mm. Suitable for buildings with a maximum height of 15m, our wall ties must be installed by competent general builders or experienced contractors in accordance with Eurocode 6 and BS 5628-3:2005. We recommend a minimum density of 2.5 ties per square meter, evenly distributed and preferably staggered.

Fire Resistance and Thermal Performance

ArmaFix Thermal Brick Ties have been rigorously tested for fire resistance and achieved an impressive 239-minute fire rating in worst-case configurations (Efectis report EFR-15-U-003794). To assess thermal performance, calculations of thermal transmittance (U-Value) should be carried out in accordance with EN ISO 6946:2007, considering a thermal conductivity of 0.59 W/m.K for the wall ties (National Physical Laboratory Report PP31/2016010220/1).

Condensation Risk and Durability

Our wall ties contribute to limiting the risk of interstitial and surface condensation, in accordance with BS 5250:2002 and BRE report (BR 262:2002). The water-shedding detail of the ArmaFix Thermal Brick Ties prevents water transfer across the ties to the inner leaf. To maintain their efficiency, keep the cavities clean and prevent fallen mortar buildup on the ties. These ties are corrosion-resistant, require no maintenance, and can provide a service life of at least 60 years.

Installation Procedure for Optimal Performance

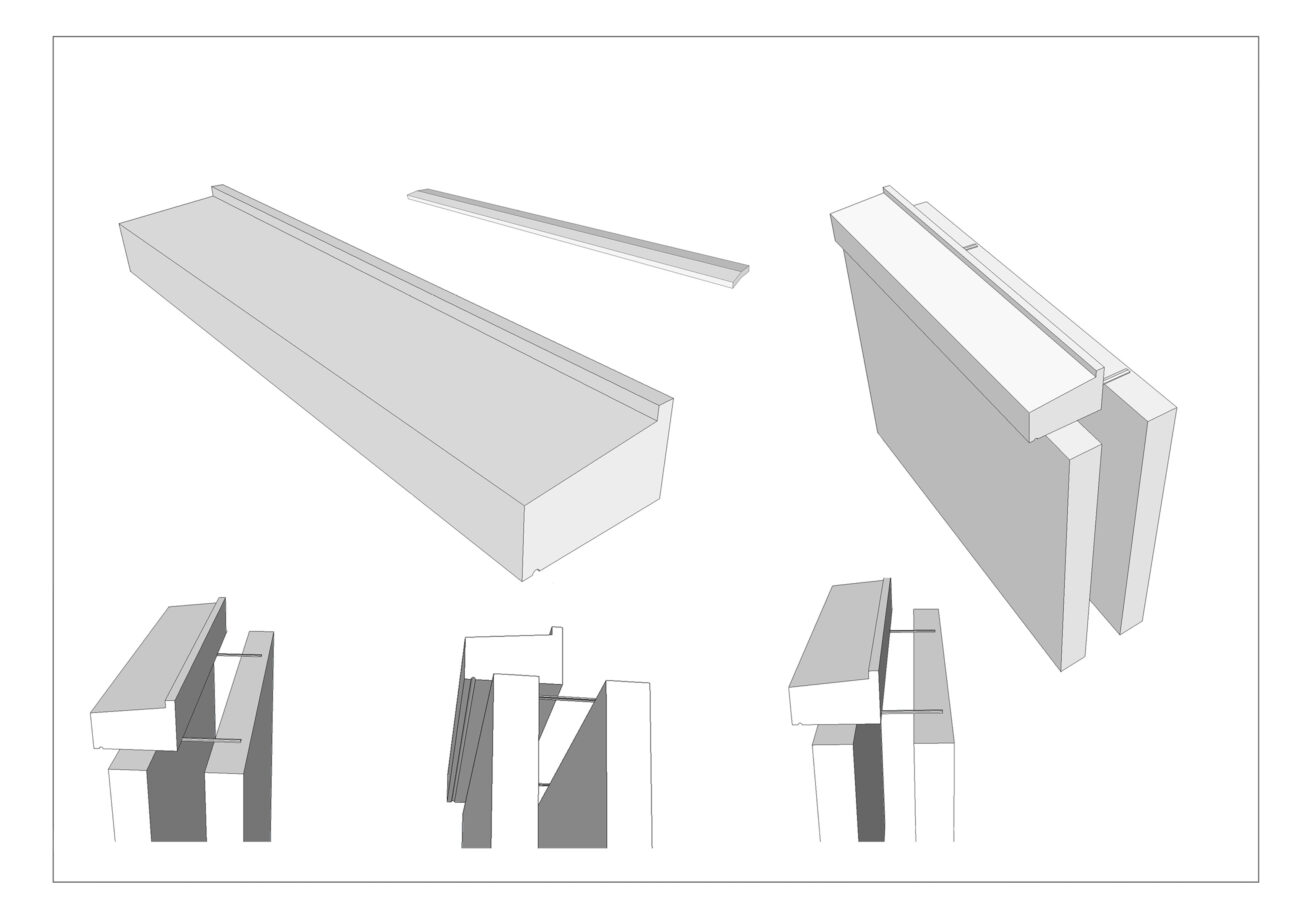

ArmaFix Thermal Brick Ties should be sandwiched between mortar joints of 10-15mm design thickness, ensuring they are fully covered. The chevron-profiled wall ties should be installed with the “hump” in the middle pointing upwards. Carefully position the ties substantially horizontally, at right angles to the wall, allowing for a slight fall from the inner leaf to the outer leaf. In partially filled cavities, notch the insulation to fit closely around the ties and use insulation clips to secure it against the inner leaf. Avoid dropping excessive mortar into the cavity and lay the first run of ties one course above the damp-proof course.

Using ArmaFix Thermal Brick Ties as Window Sill Bearers

ArmaFix Thermal Brick Ties have been tested for use in supporting precast concrete and stone window sills across a wall cavity and carry a minimum declared load capacity of 65kg across a 200mm cavity.

Relatable Product

Related products

-

Building Products

Qwik-Fix Angle™ Masonry & Stone Supports

-

Building Products

ARMATHERM THERMAL BREAKS